Time: Popularity:0times

In the realm of heating and cooling, radiators are workhorses that demand coatings as resilient as they are functional. Radiator Powder Coating emerges as a tailored solution, engineered by trusted Chinese manufacturers to meet the unique demands of radiator performance—blending high heat resistance, energy efficiency, and long-lasting aesthetics. More than just a protective layer, Radiator Powder Coating is designed to withstand repeated thermal cycles, resist oil and corrosion, and minimize energy consumption during application. Whether for residential radiators, industrial cooling systems, or automotive heat exchangers, Radiator Powder Coating delivers consistent performance that enhances both functionality and longevity, becoming a top choice for manufacturers and HVAC professionals prioritizing reliability and efficiency.

Radiator Powder Coating is a specialized thermosetting powder coating formulated explicitly for radiator substrates and high-heat-absorbing metal workpieces. Crafted with premium heat-resistant resins (typically modified polyester or epoxy-polyester blends) and performance-enhancing additives, it balances thermal stability with mechanical flexibility—critical for radiators that expand and contract with temperature changes. Unlike conventional coatings that crack or peel under repeated heating and cooling, Radiator Powder Coating maintains structural integrity, even after years of use.

Technically, Radiator Powder Coating boasts impressive metrics tailored to radiator needs. It cures efficiently at low temperatures (120°C for 25 minutes), reducing baking energy consumption by 25% compared to standard coatings. The cured film achieves Grade 0 adhesion (per ISO 2409 and GB/T 9286-1998), ensuring a tight bond with metal substrates that prevents delamination. It offers exceptional mechanical strength: impact resistance of 50 kg.cm (per ISO 6272 and GB/T 1732-1993), flexibility to bend up to 3 mm (per ISO 1519 and GB 6742-1986), and a cupping test pass at 8 mm (per ISO 1520 and GB/T 9753-1993). Its surface hardness ranges from 1H to 2H (per ASTM D3363 and GB/T 6739-1996), resisting scratches from cleaning and handling, while its salt spray resistance exceeds 1000 hours (per ISO 7253 and GB/T 1771-1991), protecting against corrosion.

Applied via electrostatic spraying—a method that ensures uniform coverage even on radiator fins and complex shapes—Radiator Powder Coating offers excellent transfer efficiency, covering 8-9 square meters per kilogram and saving 30% of raw materials. Suitable for projects of all scales, it is backed by professional technical support, allowing customization of color (per customer requirements) and finish (high-gloss, matte), while preserving its core heat-resistant and energy-efficient properties.

Radiator Powder Coating distinguishes itself from conventional coatings through a suite of radiator-specific advantages, addressing the unique challenges of high-heat, cyclic-use environments:

The defining advantage of Radiator Powder Coating is its low-temperature curing process (120°C for 25 minutes), which slashes energy consumption by 25% during production. This not only reduces manufacturing costs but also minimizes thermal stress on radiator substrates, preventing warping or damage. Its high transfer efficiency (8-9㎡/kg) further enhances cost-effectiveness, cutting raw material waste by 30%—a win for both businesses and the environment.

Radiator Powder Coating is engineered to withstand the repeated thermal cycles radiators endure. It remains flexible even after years of use, accommodating expansion and contraction without cracking or peeling. This flexibility is critical for radiators that heat up to high temperatures (often 60-80°C during operation) and cool down to room temperature, ensuring the coating stays intact and functional for decades.

Radiators are exposed to moisture, dust, and occasional oil splatters (especially in industrial or automotive settings). Radiator Powder Coating forms a dense, impermeable barrier that resists corrosion (exceeding 1000 hours of salt spray resistance) and repels oil, cooking oil, and cleaning agents. This protection extends radiator lifespan, reducing maintenance and replacement costs for homeowners, businesses, and fleet operators.

Radiator Powder Coating offers excellent leveling properties, delivering a smooth, uniform finish with high gloss and color saturation. It is available in custom colors (matched via colorimeter and visual inspection), allowing manufacturers to align radiators with interior or equipment design schemes. The hard, non-porous surface resists dust and stains, enabling easy cleaning with mild detergents—no need for harsh chemicals that damage conventional coatings.

Beyond thermal performance, Radiator Powder Coating boasts impressive mechanical durability. Its 1H-2H pencil hardness resists scratches from cleaning tools or accidental impacts, while its 50 kg.cm impact resistance protects against dents and damage during installation or use. This strength ensures radiators maintain their appearance and functionality, even in high-traffic or industrial environments.

Radiator Powder Coating’s unique blend of heat resistance, energy efficiency, and durability makes it ideal for a wide range of radiator and high-heat applications. Below is a detailed guide to its optimal use cases:

Residential and commercial (office, hotel, hospital) HVAC radiators require coatings that balance efficiency, aesthetics, and low maintenance. Radiator Powder Coating is perfect for this role: its low-temperature curing reduces manufacturing costs for HVAC brands, while its thermal stability ensures reliable performance through years of heating seasons. The custom color options allow radiators to blend with interior decor—from neutral whites for modern homes to bold hues for commercial spaces. Its easy-to-clean surface and corrosion resistance make it ideal for high-humidity environments (bathrooms, kitchens) and busy commercial settings, where radiators are frequently cleaned or exposed to moisture.

Industrial radiators and heat exchangers (used in factories, power plants, and manufacturing equipment) operate in harsh, high-heat environments, requiring coatings that withstand extreme temperatures and contaminants. Radiator Powder Coating’s 1000+ hours of salt spray resistance protects against industrial chemicals and moisture, while its thermal stability handles the intense heat generated by machinery. Its flexibility prevents cracking during thermal expansion, and its scratch resistance stands up to industrial cleaning and handling. For industrial manufacturers, Radiator Powder Coating ensures cooling systems remain functional and durable, minimizing downtime and maintenance costs.

Automotive radiators, intercoolers, and heat exchangers demand coatings that withstand high under-hood temperatures, vibration, and road debris. Radiator Powder Coating’s heat resistance handles the thermal stress of engine operation (often exceeding 100°C), while its impact resistance protects against rocks and debris kicked up by tires. Its corrosion resistance shields against road salt and moisture—critical for vehicles operating in snowy or coastal regions. The coating’s flexibility accommodates engine vibration without peeling, ensuring long-lasting performance. For automotive OEMs and aftermarket suppliers, Radiator Powder Coating delivers a reliable, cost-effective finish that meets strict automotive durability standards.

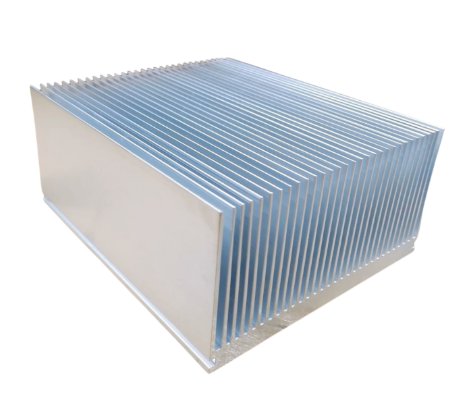

Modern electronics (servers, industrial computers, power supplies) generate significant heat, requiring small-scale radiators and heat sinks that dissipate heat efficiently. Radiator Powder Coating’s thermal stability and thin-film application make it ideal for these components: it doesn’t impede heat transfer, while its corrosion resistance protects against dust and moisture in data centers or industrial settings. Its low-temperature curing is gentle on sensitive electronic components, and its custom color options allow for branding or color-coding of cooling systems. For electronics manufacturers, Radiator Powder Coating ensures cooling components are both functional and visually consistent.

Agricultural (tractors, harvesters) and heavy machinery (construction equipment, mining trucks) radiators operate in dusty, humid, and corrosive environments. Radiator Powder Coating’s robust corrosion resistance (1000+ hours salt spray) protects against dirt, moisture, and agricultural chemicals, while its impact resistance withstands the rough handling of off-road use. Its thermal stability handles the high heat generated by heavy engines, and its easy-to-clean surface allows for quick removal of dust and debris—critical for maintaining cooling efficiency in remote locations. For machinery manufacturers, Radiator Powder Coating ensures radiators stand up to the rigors of agricultural and industrial work.

To fully unlock the performance of Radiator Powder Coating, proper application, surface preparation, and customization are essential. Here’s a practical guide for manufacturers and installers:

Radiator substrates (steel, aluminum) must be thoroughly prepared to ensure optimal adhesion. Start by degreasing and removing rust, dirt, and debris—any contaminants can cause bubbling or delamination. For ferrous metals (steel), iron phosphate or zinc phosphate pre-treatment enhances corrosion resistance; for aluminum, chromate conversion coating or sandblasting improves bonding. After pre-treatment, dry the substrate completely to avoid moisture trapped under the coating, which can compromise performance under heat.

Radiator Powder Coating is applied via electrostatic spraying. Follow these tips for consistent results:

Radiator Powder Coating is highly customizable to meet project-specific needs:

To preserve the quality of Radiator Powder Coating:

Radiator Powder Coating redefines the standard for radiator finishing, merging low-temperature curing energy efficiency, heat-resistant performance, and long-lasting protection into a single solution. From residential HVAC systems and industrial cooling equipment to automotive radiators and electronic heat sinks, it adapts seamlessly to diverse high-heat applications, delivering consistent functionality and aesthetics.

Its core advantages—energy-efficient curing, thermal stability, corrosion resistance, easy maintenance, and mechanical strength—make it a standout choice for manufacturers, HVAC professionals, and automotive engineers who refuse to compromise on performance or cost-effectiveness. Backed by professional technical support, it ensures consistent quality across mass production and custom projects, meeting the strict standards of global heating and cooling industries.

In a market where energy efficiency and durability are increasingly valued, Radiator Powder Coating offers a compelling alternative to conventional coatings. It proves that radiator finishes can be both functional and efficient, enhancing cooling system performance while reducing environmental impact and maintenance costs. Whether you’re manufacturing radiators for homes, factories, or vehicles, Radiator Powder Coating is the perfect choice for building reliable, efficient, and long-lasting heating and cooling solutions.

Would you like me to help you create a Radiator Powder Coating application checklist tailored to your specific industry (e.g., residential HVAC, automotive) to ensure seamless implementation and optimal performance?

Company Phone

+86-21-6420 0566

Working hours

Monday to Friday

Mobile phone:

13816217984

Email:

info@qinsun-lab.com